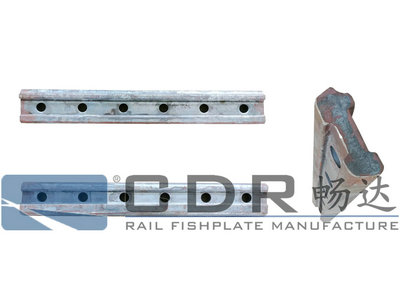

Tie Plate & Rail Base Plate

A tie plate is also called a base plate or sole plate. We specialize in producing rail fastening and tie plates is one of our main products. Base plate is used in rail construction to support the rails. We can offer base plate made using either casting iron or casting steel for customers to choose from, depending on the load and the type of rails. Boltable as well as weldable clips can be applied. For the discontinuous type of support, we supply various ribbed tie plate which are also produced in casting iron or casting steel.

Tie plates are generally used to take the load of rail and distribute the load to the sleepers offering proven economies. We manufacture all types of railroad plate s suitable for various rail sections, for use on wooden, steel or concrete sleepers and ballast-less tracks used with elastic fastenings on wooden sleepers and 'K' type fastening system.

Tie plates made of Cast iron or steel can be the welded or fabricated type, depending upon the customers requirements.Our railroad tie bar can be made to suit various rail section, i.e. UIC 60, UIC 54, RN 45, 90 A, etc

Tie plate or sole plates are needed in rail installation, as they not only support the rails, but also enable the entire fastening system to be fixed on. Rail tie plates are the uppermost component of a crane rail or track support system. The primary function of a tie plate or sole plate is to provide the rail with a flat, smooth resting surface while allowing for vertical alignment of the rail system. Tie plates are secured by Anchor Bolts, also known as Holding Down Bolts. Sole plates are typically installed with a layer of grout cast beneath, which fills the void between the soleplate and the concrete foundation

The holes for bolting the anchor and leveling bolts, and holes for bolt through clips if present, are precisely drilled into the sole plates. For weldable clips and base clips, the bottom of the clip is welded onto the sole plates before galvanizing.